The salt kiln produces pots with a great deal of variety and surface interest. Before the pots are loaded into the kiln they are textured and decorated with coloured slips. During the last stages of the firing, salt is introduced into the kiln. The salt vaporizes in the intense heat and then combines with silica in the clay to form the glaze that coats the surface of the pot. As the hot gases circulate in the kiln, the pots are exposed unevenly to the salt which creates the variations seen in the finished surface.

The kiln is loaded and ready for firing. Bricks will be placed in the door to close the kiln.

Elaine adds salt to the kiln with assistance from Jack Ploesser.

Elaine pulls a ring to check for glaze development.

Enter Text

Enter Text

The top photo is before the firing. The bottom photo is the same shelf after the firing. Note the temperature indicating “cones” which are upright in the top photo have melted and the glaze rings have been removed during the firing.

Enter Text

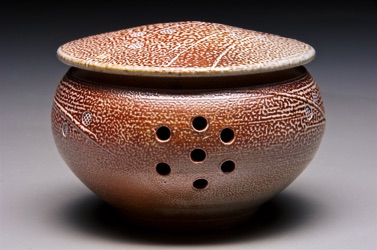

Salt fired pots often have the characteristic “orange peel” surface shown on the garlic pot above. The vases on the left have this mottled surface on the blue areas but are completely smooth in the red area.